The #1 Choice of Experienced End-Users and OEMs

End-Users choose DynaCHARGE™ to replace competing devices and opacity more than any other brand. OEMs choose DynaCHARGE™ more than any other brand.

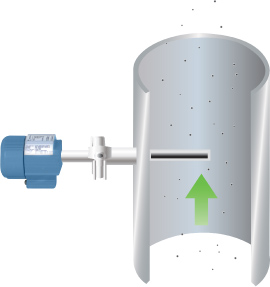

As particles flow by a sensor, charge is induced into the sensor creating small currents in the picoamp (pA) range. The signal is processed into an output proportional to mass.

FilterSense invented particulate monitoring using charge induction and remains the technology leader.

Reliable

Prevent False Alarms

Fully insulated probes prevent false readings from moisture, corrosives, and most conductive particles – without air purge.

Low Maintenance

Typically maintenance free where competing products and optical monitors can have 1–3 month cleaning intervals.

Durable

Sensors are free of electronics on most models (optional on all). Removing electronics from heat and vibration increases performance and life. It enables intrinsic safety approvals and provides safe, easy access to the controls since many filtration monitoring points can be difficult to access.

Stringent Quality

ISO 9001 certified design and manufacturing, accelerated life testing in the design stage (HALT), thermal stress testing prior to shipment, conformal coating circuits, and quality packaging further ensure reliability.

Easy To Use

Installation

No critical alignment (like optical monitors) and otherwise straightforward installation.

Simple Operation

The output is absolute and there are no confusing adjustments or blind auto-set functions.

High Precision When You Need It

High-precision options provide superior low-level detection and increased linearity for mass correlations. Front-end circuit resolution of 0.01 picoamps, high-attenuation filtering, temperature compensation, and advanced signal processing combine to provide exceptional performance.

DynaCHARGE™ vs. Competition Charge Sensing

Waste to Energy Plant

DynaCHARGE™ vs. Optical Forward Scatter

Aluminum Gas Treatment Center

EPA Compliant

DynaCHARGE™ models are available for all categories of EPA PM CEMS compliance (output in mg/m3, relative mass monitoring, and leak monitoring). Instrument performance and internal self-checks meet corresponding standards, such as ASTM D7392 (relevant to US-EPA MACT), NAMUR NE 107 and similar MCERTS and EN standards.